I knew it wouldn’t be too long before someone looked at the current 3D concrete-printed house and said, “I can do that better and help the environment at the same time.”

Building a house is time-consuming, requires a large number of raw materials and labor, and is not environmentally friendly. Now, imagine a world where houses are built quickly, yet affordable and even sustainable. This may sound surreal, but it is actually happening according to an article in INHABITAT.

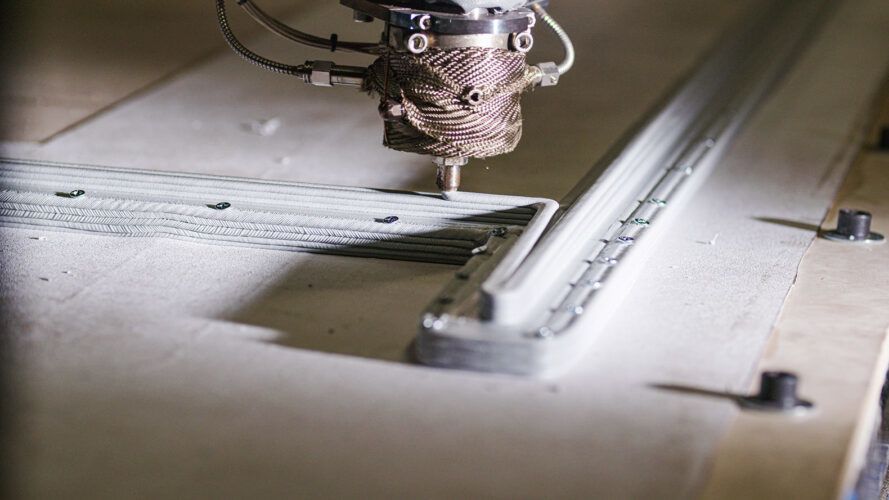

Azure Printed Homes, a Los Angeles-based startup, is putting plastic to good use by using it to build 3D-printed homes. The company offers sustainable solutions to two problems: plastics waste and housing shortages. Azure printed homes was founded by entrepreneurs Ross Maguire and Gene Eidelman. The company was recently chosen by the real estate development firm Re-Inhabit to construct 10 rental homes in Southern California.

Furthermore, they follow a sustainable approach to making a house. The process is efficient and reduces the environmental impact. According to the company, it can build homes 70% faster and 30% cheaper compared to the “traditional home construction methods.” The Azure homes are constructed in their Culver City factory and then delivered to the site.

Additionally, the house is said to be 99% finished when it leaves the factory. Following that, it is transported to the destination on a flatbed truck. Once on-site, the only thing left to do is connect the modules together. The printing process takes nearly a day after the house design is finalized. They highlight that over 60% of the print material comes from plastic used in food packaging and plastic bottles. A small house (180 square feet) could be constructed using 100,000 recycled plastic water bottles.

CLICK HERE to read the entire INHABITAT article

Gary Fleisher, Contributing Editor