The construction industry has seen a significant evolution over the years, with innovations and technological advancements shaping the way we build structures. One of the key developments in recent times is Modern Methods of Construction (MMC). MMC represents a departure from traditional on-site construction methods, aiming to enhance efficiency, sustainability, and overall quality in the construction sector.

photo – showhouse UK

By looking deeper into MMC in detail, highlighting various techniques and practices that fall under its umbrella and their potential benefits, we can see why offsite construction will continue to grow and within the foreseeable future, become the preferred way to build.

Prefabrication and Modular Construction

Prefabrication stands as a cornerstone of MMC. It involves the manufacturing of building components, such as walls, floors, and roof trusses, in a factory or off-site location. These prefabricated components are then transported to the construction site and assembled. This approach offers numerous advantages. By fabricating components in a controlled environment, the construction process becomes less susceptible to weather-related delays, resulting in faster project completion times. Additionally, the quality of the components can be more closely monitored and controlled, reducing the risk of defects or errors during construction.

photo – Landsec

Taking prefabrication a step further is modular construction. In this approach, entire building modules or units are created in a factory. These modules can be designed and customized to fit specific project requirements and can include everything from walls and ceilings to plumbing and electrical systems. Once produced, these modules are transported to the construction site and assembled, often through stacking or interconnecting them to form a complete structure. This method is particularly popular in the construction of modular homes, hotels, and other multi-unit buildings. The benefits of modular construction include improved quality, shorter construction schedules, and reduced waste generation.

3D Printing

Another groundbreaking technology within MMC is 3D printing. This cutting-edge technology enables the creation of structural components and even entire buildings layer by layer, using materials such as concrete or plastic. 3D printing offers the advantage of precision and customization, allowing architects and builders to realize complex and unique designs that may be challenging to achieve through traditional construction methods.

This technology has the potential to significantly reduce material waste, enhance construction speed, and open up new design possibilities.

Digital Design and Building Information Modeling (BIM)

Advanced digital design tools and Building Information Modeling (BIM) software play a crucial role in MMC. Architects and engineers utilize these tools to create highly detailed 3D models of buildings before construction begins.

These models facilitate collaboration among project stakeholders and enable accurate planning. By identifying potential issues and conflicts in the virtual environment, errors and inefficiencies can be minimized, resulting in smoother construction processes and cost savings.

Cross-Laminated Timber (CLT)

Cross-Laminated Timber (CLT) is an engineered wood product gaining prominence in MMC. It is produced by stacking layers of timber at right angles and bonding them together. The result is a strong, lightweight, and sustainable building material. CLT has found extensive use in the construction of various types of buildings, including tall structures.

Its eco-friendly properties make it an appealing choice for environmentally conscious projects.

Pre-Engineered Buildings

Pre-engineered buildings are a practical embodiment of MMC principles. These structures are designed and fabricated off-site according to standardized specifications. They are particularly common in industrial and commercial applications due to their cost-effectiveness and rapid assembly.

The use of pre-engineered components streamlines the construction process, reducing both time and labor costs.

photo – Fabricon Modular

Steel Frame and Concrete Panel Systems

MMC encompasses various systems that enable the off-site fabrication of structural elements. Steel frame structures, for instance, are manufactured off-site and can be swiftly assembled on-site.

Similarly, concrete panels are precast off-site and can be employed to enclose the building’s structure. These systems expedite construction and offer high precision and consistency.

Off-Site Services and Systems

In addition to building components, MMC extends to off-site services and systems. Plumbing, electrical work, and HVAC system fabrication are examples of services that can be pre-assembled and tested before being transported and installed on-site. This approach significantly reduces construction time, minimizes disruptions, and enhances the overall efficiency of the project.

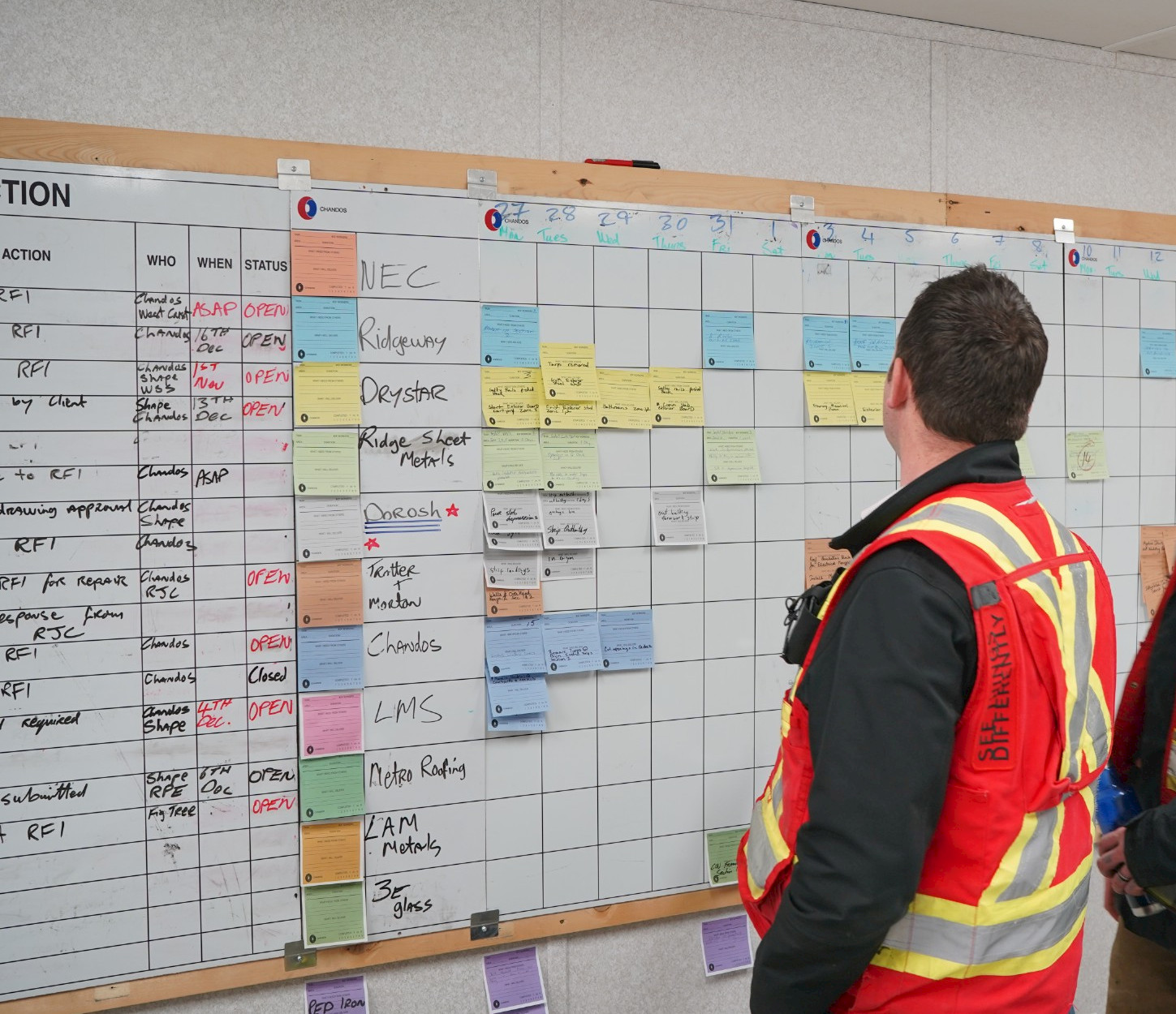

photo – Chandos Construction

Lean Construction

Lean construction principles are integral to MMC. They focus on reducing waste and maximizing efficiency throughout the construction process. This may involve improved project management, supply chain optimization, and more efficient allocation of resources. Lean construction contributes to cost savings, shorter project durations, and a more sustainable approach to construction.

Green and Sustainable Technologies

Environmental sustainability is a fundamental consideration in MMC. Many MMC projects incorporate green and sustainable technologies, such as solar panels, rainwater harvesting systems, and energy-efficient insulation. These features contribute to the creation of environmentally friendly buildings that are energy-efficient, reduce resource consumption, and have a lower environmental impact.

Modern Methods of Construction (MMC) represent a significant shift in the construction industry, offering innovative techniques and practices that enhance efficiency, sustainability, and overall quality. By leveraging off-site manufacturing, automation, and advanced materials, MMC methods can lead to reduced construction time, cost savings, improved quality control, and a reduced environmental impact.

In a world with evolving challenges, such as labor shortages and the imperative for more sustainable construction practices, MMC stands as a valuable solution for addressing these issues and shaping the future of construction.

Top photo – Autovol

.