There are so many moving parts to building a Net-Zero structure that we probably won’t see a true Net-Zero home in our lifetimes. Oh, No! That can’t be right.

Is it possible to deliver a construction project without carbon emissions? The answer is no and, in all likelihood, it never will be.

There are many parts to the problem of CO2 emissions and climate change. The concept of net zero greenhouse gas emissions was first popularised by the Paris Agreement, a landmark deal that was agreed upon at the United Nations Change Conference (COP21) to limit the impact of greenhouse gas emissions.

Until recently those low-carbon materials were not easy to come by at a scale that could make a significant difference to the industry. Add to that the high cost of using these newly-developed materials and newly-developed manufacturing processes, and it was difficult to see how they could really have an impact on overall construction emissions.

It would appear, however, that change is coming – and coming in the form of new low-carbon-cement technologies. Cement is the world’s largest manufactured product by mass and is responsible for more than 7% of global carbon emissions, this could be very good news.

The bottom line is there is a lot more to Net-Zero than just the reduction in carbon alone.

EMBODIED CARBON/CARBON FOOTPRINT

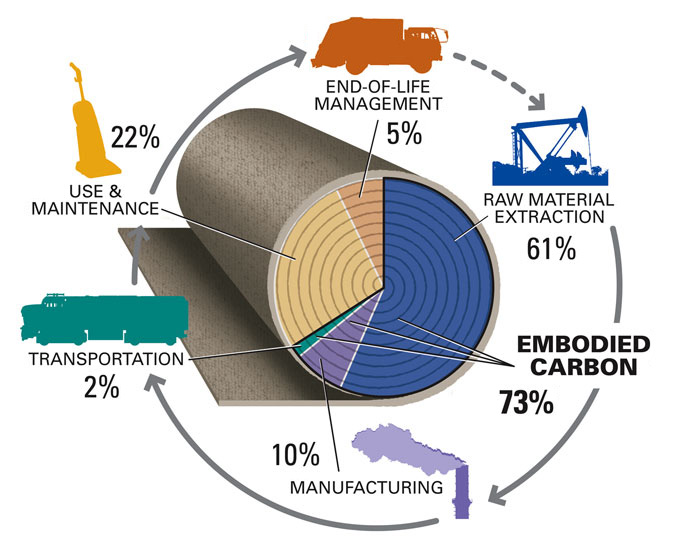

Embodied carbon consists of all the GreenHouse Gas emissions associated with building construction, including those that arise from extracting, transporting, manufacturing, and installing building materials on site, as well as the operational and end-of-life emissions associated with those materials.

It is often equated with the carbon footprint of a building or infrastructure project before it becomes operational. It also refers to the CO₂ produced by maintaining the building and eventually demolishing it, transporting the waste, and recycling it.

One of the main methods to reduce embodied carbon is by using more resilient materials that will last longer and are often produced via a more efficient construction process.

NET ZERO

What exactly does Net Zero mean? Put simply, net zero refers to the balance between the amount of greenhouse gas produced and the amount removed from the atmosphere. We reach net zero when the amount we add is no more than the amount taken away.

Net Zero means cutting greenhouse gas emissions to as close to zero as possible, with any remaining emissions re-absorbed from the atmosphere, by oceans and forests.

How do we achieve net zero?

The most feasible pathways to net-zero emissions include four main strategies:

- Generate electricity without emissions. …

- Use vehicles and equipment that are powered by electricity instead of fossil fuels. …

- Use energy more efficiently. …

- Remove carbon dioxide from the atmosphere.

PLITEQ recently published an article showing the carbon footprints of 9 building materials from the lowest to the highest.

1. Rammed Earth

Rammed Earth ranks as the lowest in carbon footprint, as it is basically an ancient technique that only uses natural raw materials such as earth, chalk, lime, and/or gravel. It is considered to be the most sustainable building method. With an average of 48kg embodied carbon per m³, it is slowly making a revival in modern buildings as it is good for the environment and has a unique and beautiful aesthetic.

2. Softwood Timber

Second most environmentally friendly building material to produce is Softwood Timber. Softwood is wood from gymnosperm trees such as pines and spruces, while hardwood is from angiosperm trees such as oaks and maples. Softwood timber emits on average 110kg embodied carbon per m³, making it a great choice to use as a finishing material for buildings, especially residential buildings.

3. Cross Laminated Timber

Third on the list for most environmentally friendly building materials is the Cross Laminated Timber. It is a very common building material used in large scale buildings, as it offers high design flexibilities, very lightweight yet very strong, easy to install, and generates almost no waste on construction site. Cross Laminated Timber is also very effective in acoustic and thermal performance. It is created by stacking several layers of dried lumber boards in opposing directions, then bonded with structural adhesives to create a straight rectangular panel. Averaging about 219kg embodied carbon per m³ in emission, Cross Laminated Timber is one of the most used building material today for its low carbon footprint.

4. Stone

Next up is Stone. Stone is one of humanity’s first building material, and it is as straightforward as it sounds. Stone is great in that it requires basically no manufacturing to produce as it is a fully natural raw material, and it is so durable that structures that are built thousands of years ago are still standing strong to this day. Stone emits about 237kg embodied carbon per m³, making it a very solid choice (no pun intended) for building materials.

5. Clay Brick Wall

Fifth on the list is Clay Brick Wall. Similar to Stone, Clay Brick is also one of the oldest building materials and has been used in early civilizations. It is very easy to produce, resistant, and durable to all weather conditions. Just like Stone, many structures produced with Clay Brick centuries ago are still standing strong to this day. Its production is very simple; it is simply mixing clay and water. Averaging 345kg embodied carbon per m³, it puts Clay Brick as a decent choice of material for constructing buildings with a carbon footprint in mind.

6. Reinforced Concrete

Starting to reach the high end of the carbon footprint list, is Reinforced Concrete. Concrete has a low tensile strength, and are usually reinforced by steel bars inside to make is suitable for buildings. Reinforced concrete is the most common material used today for constructing the foundation stages of a building (walls, foundation, columns, etc.) With an average of 635kg embodied carbon per m³ during the production and use of Reinforced Concrete, it makes it one of the most harmful material to our environment due to how it is commonly used and relied upon.

7. Glass

Seventh on the list for least environmentally friendly building material is Glass. Glass is by far a building material that we see the most today; it exists in pretty much every single building on the planet. There are laws that require structures to have a certain percentage of natural light to enter into it, making Glass a must-use material. Unfortunately, Glass on average produces 3600kg embodied carbon per m³, which is a significant jump from the previous materials on the list.

8. Steel Section

Second most unsustainable building material is the Steel Section. Out of all the industries, the construction industry uses steel the most, accounting for more than 50% of the world’s demand for steel. It’s very flexible in design, affordable, and strong, but the carbon footprint that is produced from the manufacturing process to delivering is immense. With another significant jump from Glass, it carries on average 12090kg of embodied carbon per m³.

9. Aluminum

Last but not least, the one material that leaves the most carbon footprint is Aluminum. Along with Brick, Cement, and Steel, Aluminum is considered today as one of the most critical construction material. It is also an abundantly available natural resource. It is commonly used because it has a high strength to weight ratio, easy to use, low transportation cost, and low maintenance. However, the carbon footprint of aluminum is especially high compared to the rest of the list, as it brings on 18009kg of embodied carbon per m³ on average.

Gary Fleisher, Contributing Editor