This is a question several modular home factory owners have asked me over the past few years and my answer is always “if not already, they should be!”

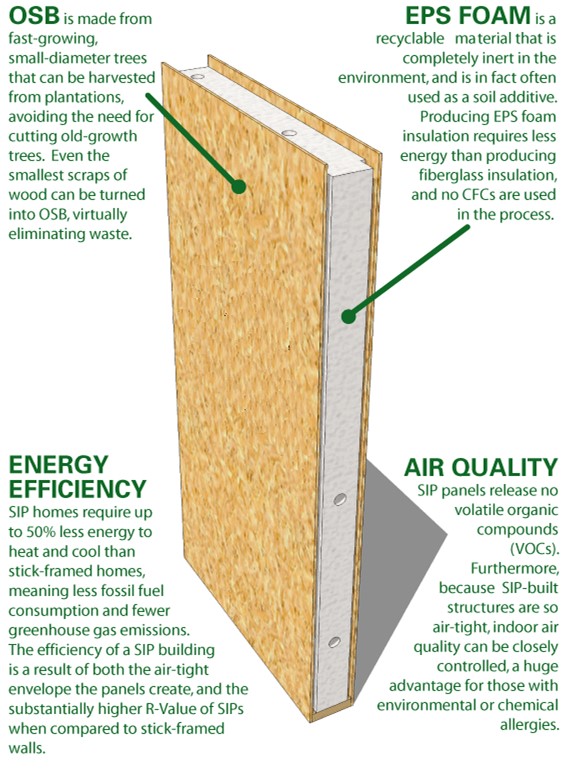

Structural insulated panels (SIPs) are high-performance building systems for residential and light commercial construction. The panels consist of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB). SIPs are manufactured under factory-controlled conditions and can be fabricated to fit nearly any building design. The result is a building system that is extremely strong, energy-efficient, and cost-effective.

SIP panels deliver unrivaled insulation and airtightness, which reduces energy costs over the building’s lifetime. SIPs are known to be about 50% more energy-efficient than traditional timber framing. A SIP building envelope has minimal thermal bridging and delivers excellent airtightness, which lends itself ideally to LEED and net-zero-ready building standards.

The one fear every modular factory person seems to have with SIP Panels is how to run the electrical. If that is the only problem they are concerned about, then let’s find a way quickly and begin building with them.

A SIP home or commercial building allows better control over indoor air quality because the airtight building envelope limits incoming air to controlled ventilation which filters out contaminants and allergens. The SIP envelope doesn’t have the voids or thermal bridging of conventional stick framing that can cause condensation leading to potentially hazardous mold, mildew or rot.

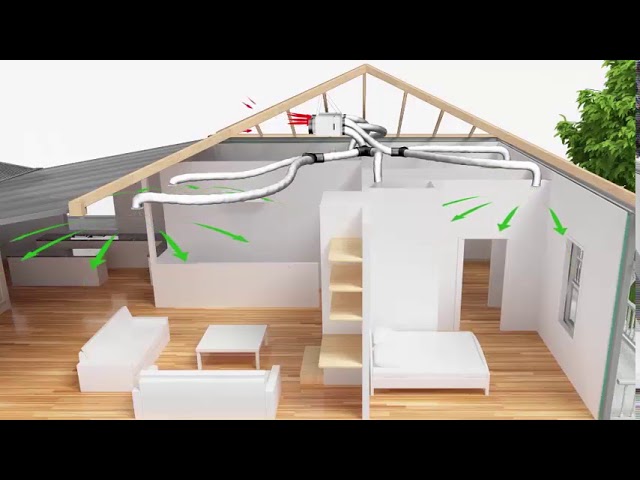

Since traditional ventilation systems would compromise the energy efficiency provided by SIPs’ airtightness, a special system known as MVHR (Mechanical Ventilation with Heat Recovery) provides fresh filtered air into a building whilst retaining most of the energy that has already been used in heating the building. Heat Recovery Ventilation is the solution to the ventilation needs of energy-efficient buildings.

SIPs are highly energy-efficient and therefore contribute positively to the environment by reducing CO2 levels. They also use significantly less energy during the manufacturing process compared to traditional construction methods and have lower embodied energy than traditional construction materials, such as steel, concrete, and masonry.

SIP walls and roofs are designed and precisely manufactured offsite meaning that modular factories can reduce the amount of space needed to store structural lumber and insulation as both are found in the SIP, which can be ordered as needed.

There are a lot of advantages over traditional modular wall systems including your homes can withstand harsh weather conditions and extreme climates because when complete, they form a monolithic shell that is seven times stronger than a traditional timber framed shell.

Even though SIPs have been around for decades, they are still relatively new and only a handful of builders and factories have experience with them.

The disadvantages of SIP panels are almost the same as any timber-framed home, they are susceptible to moisture problems. One solution you can use is to have the outer skin of the SIP be moisture resistant, something most SIP factories opt for.

With all the advantages of using SIPs in your factory’s assembly line, why is running electrical through the panel something you fear?

By the way, the SIP people have answers to that as well!

Gary Fleisher, Contributing Editor