In modular home production, the terms “automation” and “robotics” often surface. While they may seem synonymous, each denotes a specific technology and function within the manufacturing process. This distinction is crucial for manufacturers looking to optimize their production workflows. Let’s dive deeper into these concepts to clarify their roles, impacts, and how they interplay to revolutionize the modular home industry.

all photos- Homag

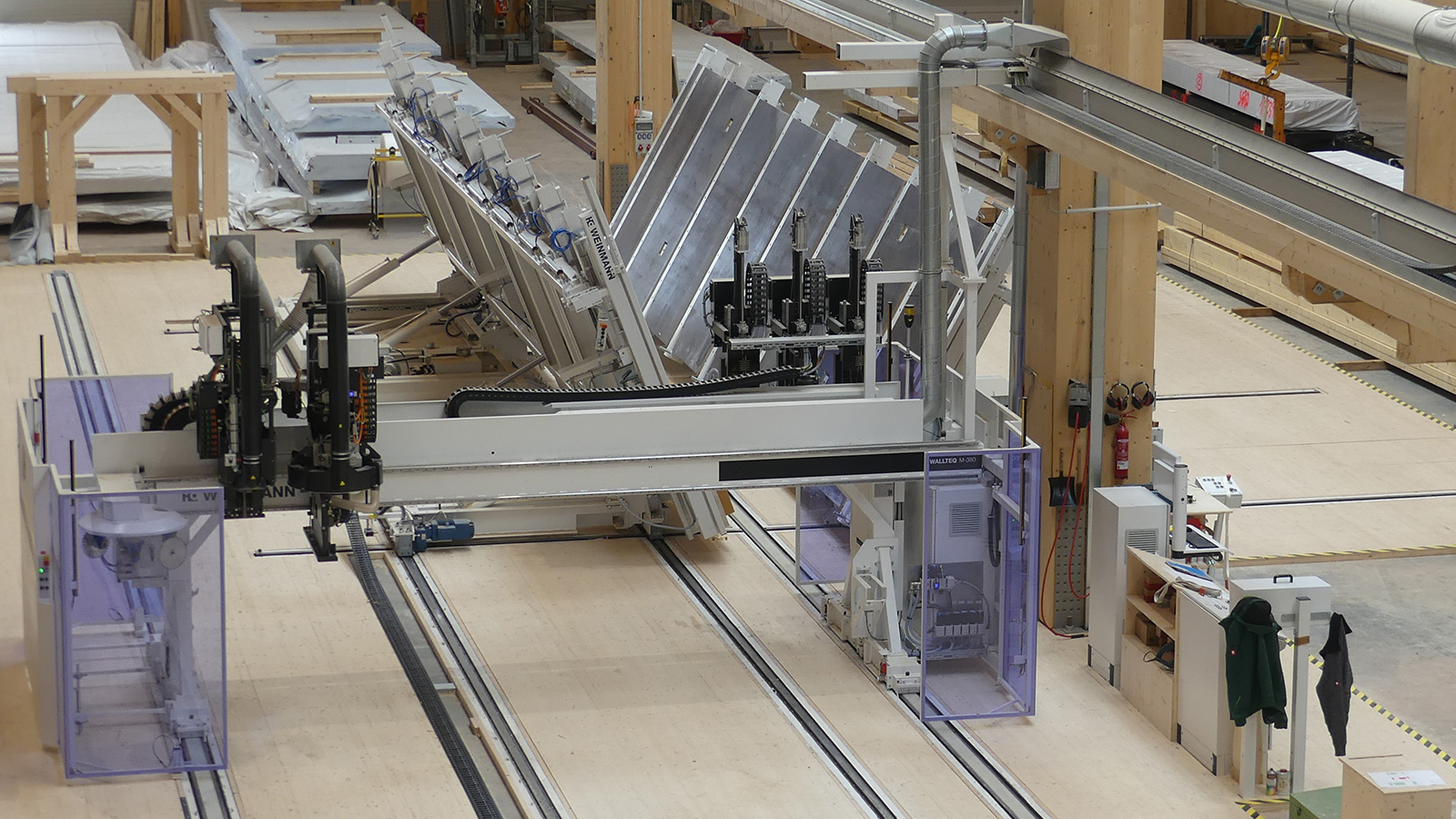

Understanding Automation in Modular Home Production

Automation encompasses the use of control systems, including computers and robots, to manage and control various processes and machinery with minimal human intervention. Here’s what makes automation a game-changer in modular home production:

Process Control: At its core, automation employs technology to oversee different stages of manufacturing—from the intake of raw materials to the final assembly of modules. It incorporates automated processes such as cutting wood and painting, activities that historically required manual labor. This shift not only speeds up production but also enhances precision.

Efficiency and Consistency: The primary objective of automation is to bolster production efficiency and maintain consistency across the board. Automated systems can function continuously, day and night, ensuring uniform quality while minimizing the risks associated with human error.

Scalability: A significant advantage of automated systems is their scalability. Depending on market demands, production can be adjusted upwards or downwards without major alterations to workforce levels, thus providing flexibility and cost efficiency.

Software Integration: The integration of software systems, such as CAD for design, manufacturing execution systems, and materials requirement planning, streamlines the entire production lifecycle, from design through to manufacturing and distribution.

.

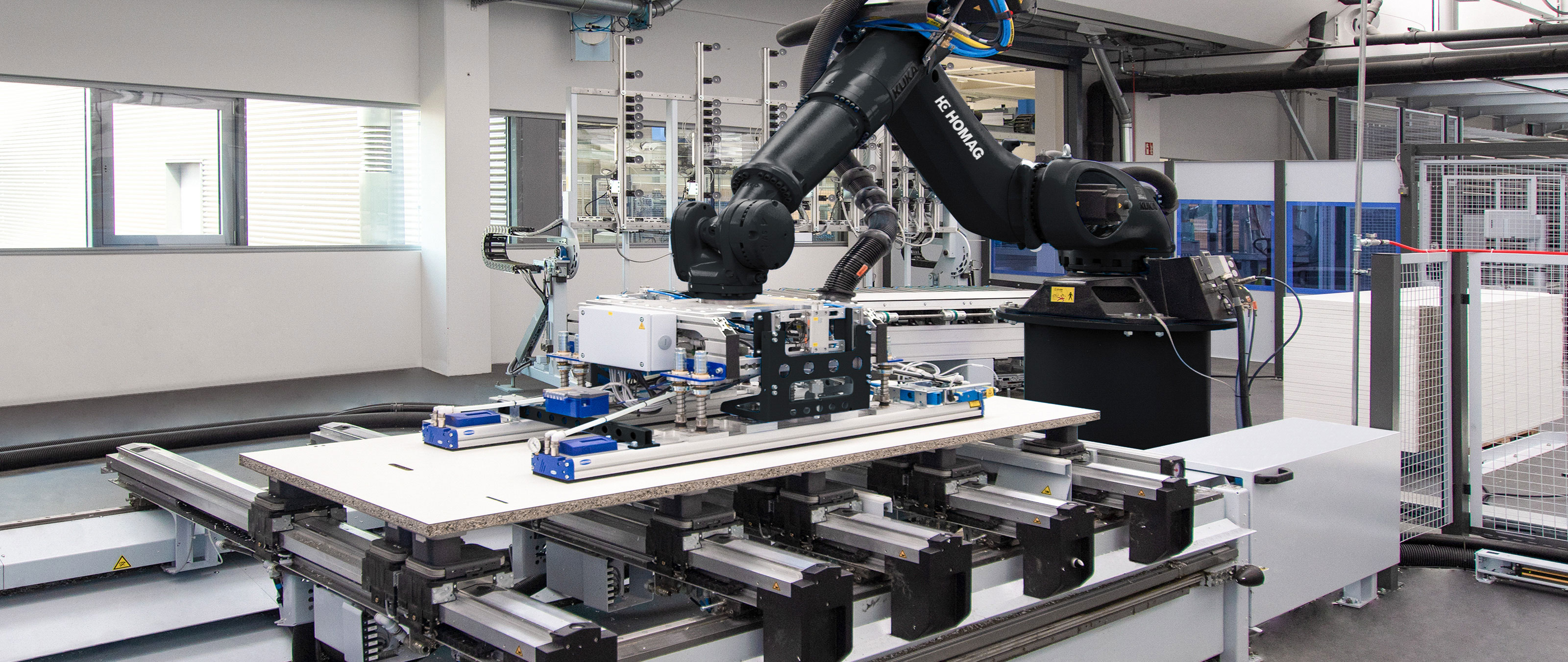

The Role of Robotics in Modular Home Production

Robotics, a subset of automation, specifically involves the use of robots to execute particular tasks within the manufacturing process. Here’s how robotics is making its mark:

Task-Specific Operations: In modular home factories, robots perform programmed tasks like welding, lifting heavy components, assembling parts, and applying sealants. Each robot is fine-tuned to execute these tasks with high speed and precision.

Enhanced Capabilities: Robotics technology is particularly useful for handling tasks that are either too dangerous or intricate for human workers. This includes operations requiring high precision cuts or activities in potentially hazardous environments.

Human-Robot Collaboration: Modern production lines often see robots working alongside human workers, creating a collaborative environment where robots handle the more physically demanding or risky tasks, thereby enhancing safety and efficiency.Adaptability and Learning: Advanced robots are not only programmable for a variety of tasks but are also capable of learning from their operations. Through machine learning techniques, they continually refine their performance, making them increasingly effective over time.

Key Differences Between Automation and Robotics

.

Scope: Automation is an overarching term that includes various technologies used to enhance production efficiency, including robotics. Meanwhile, robotics refers specifically to the application of robots in the production process.

Application: Automation can be implemented across all levels of production, from material handling to final assembly, primarily through software and technological control systems. Robotics, on the other hand, is specifically about the physical employment of robots to perform distinct tasks.

Complexity and Investment: Setting up robotics in a factory typically requires a higher initial investment and more sophisticated setup compared to broader automation technologies. Nevertheless, the deployment of robotics can substantially elevate production capacity and product quality.

While robotics is inherently a part of automation, not all automation involves robotics. Each plays a pivotal role in the modernization and efficiency improvement of modular home production. By leveraging both automation and robotics, manufacturers are equipped to meet growing market demands with unprecedented quality and efficiency. This nuanced understanding helps stakeholders make informed decisions that drive innovation and competitiveness in the industry.

.

Gary Fleisher is a renowned blogger, consultant, and commentator on construction and housing trends, known for his insightful analysis of the industry.